In an industrial world undergoing radical change, the challenges are major. They are first and foremost technological, as products and services have to be adapted to the challenges of lower pollutant emissions. But industry must also adapt to new constraints linked to high variability and uncertainty over product lifetimes and associated volumes, while keeping manufacturing costs under control.

From process engineering to product co-development

Drawing on over 35 years' experience in the design. production facilities, OSE has decided to offer its customers support in the overall product development process, in order to integrate these new constraints. In a world where innovation is everywhere, integrating process constraints right from the upstream design phases, while bringing in industrial know-how and innovative technologies, is a guarantee of success.

In this way, through an iterative approach based on agile methods, each sprint leads to a concrete result, a deliverable, which ensures control of the overall development cycle. Our perfect knowledge of manufacturing processes and our ability to propose software-driven production solutions enable us to provide not only a global response in terms of engineering, but also one adapted to market constraints (from the size of the average batch to the cost price ex-factory).

OSE has integrated a number of experts (electromagnetics, thermics, finite elements, power electronics, on-board computing, etc.) into its environment, so as to be able to dialogue more easily with its customers, and in particular with their R&D units.

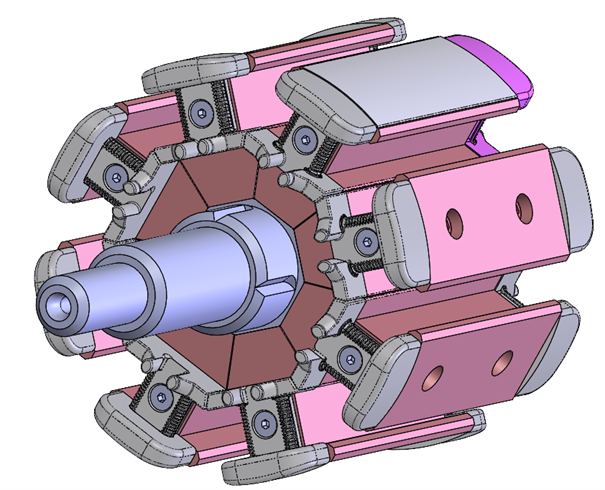

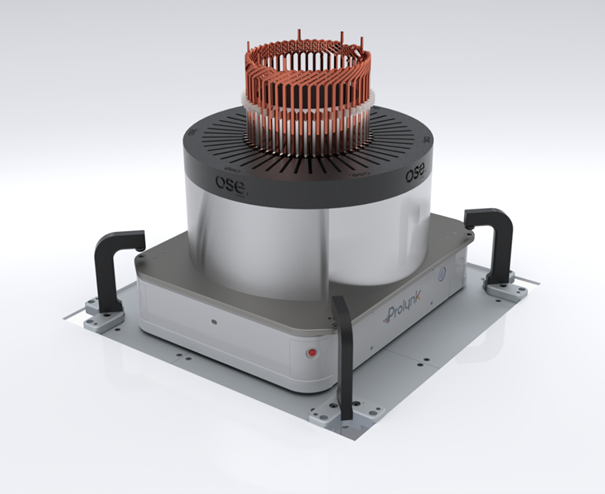

The latest example is the development of a stator for the aerospace industry

By integrating specific technical skills in the forming of copper alloy flats, as well as in the evaluation of assembly solutions to ensure productivity and quality/repeatability of welded joints using new technologies, we succeeded in co-developing with our customer a product whose performance exceeded by more than 25% the usual performance of the old motors that this re-engineering phase was designed to replace.

Up to the production of representative samples

Our application laboratories are at the service of overall project performance, and we can put our laboratory machines at the service of proofs of concept, prototypes or pre-production runs.

In this way, we are able to produce the few head-of-series that will enable us to evaluate or even certify products that have been produced on equipment very close to that used for series production.

For more information on our winding solutions and technologies,

please contact us at the following address:

sales.ew@ose-group.com